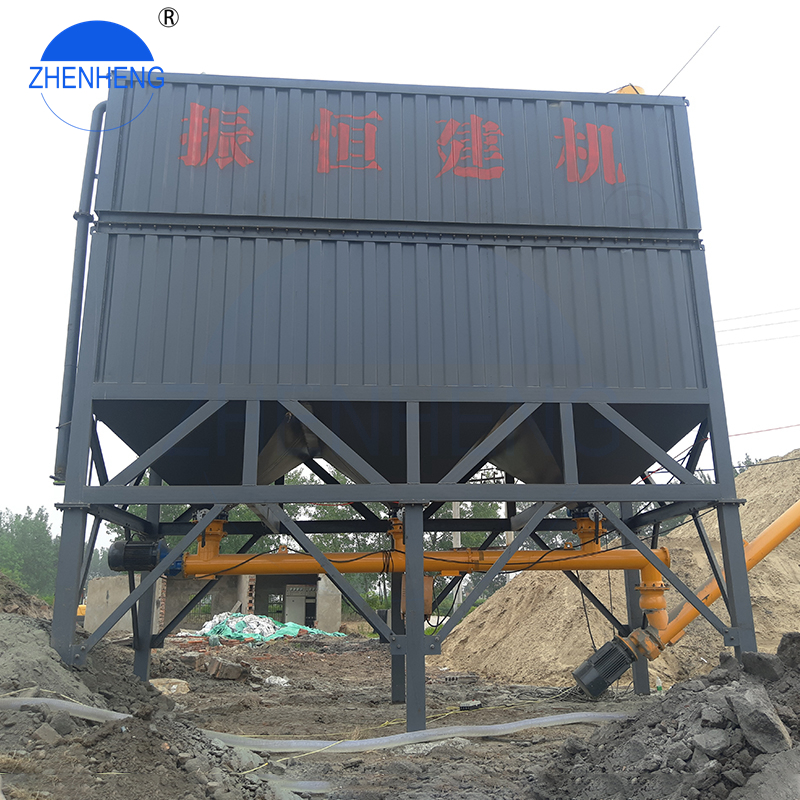

Horizontal Concrete Cement Silo Fly Ash Silo 50T 80T 100T 200T Cement Storage Tank Mobile Cement Silo

Product Description

Structure analysis: Steel structure of warehouse body, screw conveyor, ladder, guardrail, feeding pipe, exhaust pipe, dust collector, pressure safety valve, high and low material level gauge, discharge valve, etc.

Features:

1). No installation required, easy to use. After the horizontal cement silo is integrally welded in the factory, it is transported to the construction site and ready for use. Compared with the traditional circular cement silo, there is no need to pre-embed the installation foundation, and it is fixed by welding.

2). The height is reduced for easy placement. Compared with the traditional vertical cylindrical cement silo, the horizontal cement silo is much lower in height, so that it can be placed flexibly without being too conspicuous, with strong concealment and reduced environmental protection inspections.

3). No need for external encapsulation. At present, the country has strict requirements on the environmental protection measures of enterprises, and the same is true for the mixing station industry. Environmental protection regulations: For the exposed warehouse equipment, external packaging must be carried out. Due to the advantages of low height and easy placement, the horizontal cement silo can be installed in the workshop, thereby avoiding external packaging and reducing enterprise costs.

Details:

1. Dust Collector

The top of the cement silo is equipped with a dust removal device (electric or pulse), which can effectively absorb the suspended particles in the silo and reduce the pollution to the surrounding environment.

2. Butterfly Valve

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

2. Butterfly Valve

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

3. Level Gauge

The cement silo material level device can sense the storage height of the material in the silo.

4. Arch Breaking Device

The lower cone of the cement silo is equipped with an air blowing arch breaking device, which uses a small electromagnetic reversing valve in the air control box to control the release of compressed air to break the arch of cement and various powder materials to avoid powder accumulation and blockage.

4. Arch Breaking Device

The lower cone of the cement silo is equipped with an air blowing arch breaking device, which uses a small electromagnetic reversing valve in the air control box to control the release of compressed air to break the arch of cement and various powder materials to avoid powder accumulation and blockage.

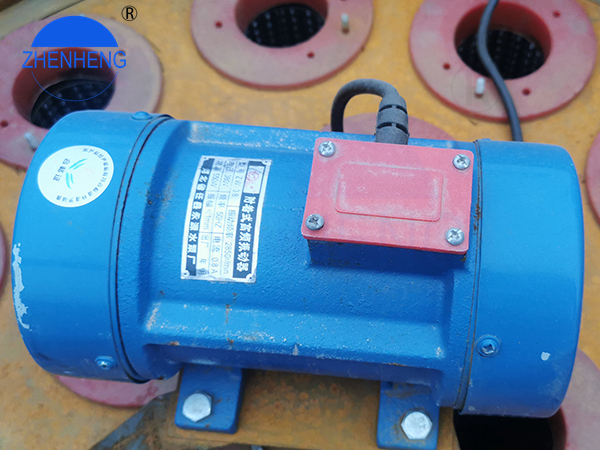

5. Vibrator

The cement powder in 50kg/100kg type or jumbo bag type can be transferred to mixer through cement hopper and screw conveyor. There is a blade inside the cement hopper, which can damage the bag, drop the material into the bottom, and send it to the mixer by screw conveyor.

Parameters

|

Horizontal Cement Silo |

||||

|

Model |

Length---mm |

Width---mm |

Height---mm |

Match Mixer |

|

30T |

6000 |

2200 |

2380 |

JS500 |

|

50T |

9600 |

2200 |

2380 |

JS500 |

|

60T |

10600 |

2200 |

2380 |

JS500 |

|

80T |

11300 |

2300 |

2380 |

JS750 |

|

100T |

12100 |

2500 |

2800 |

JS1000 |

|

120T |

12900 |

2550 |

2900 |

JS1000 |

|

150T |

13300 |

2600 |

3000 |

JS1000 |

|

200T |

14300 |

2700 |

3300 |

JS1500 |

|

300T |

15300 |

3000 |

3500 |

JS2000 |

|

500T |

17300 |

3600 |

4000 |

JS3000 |