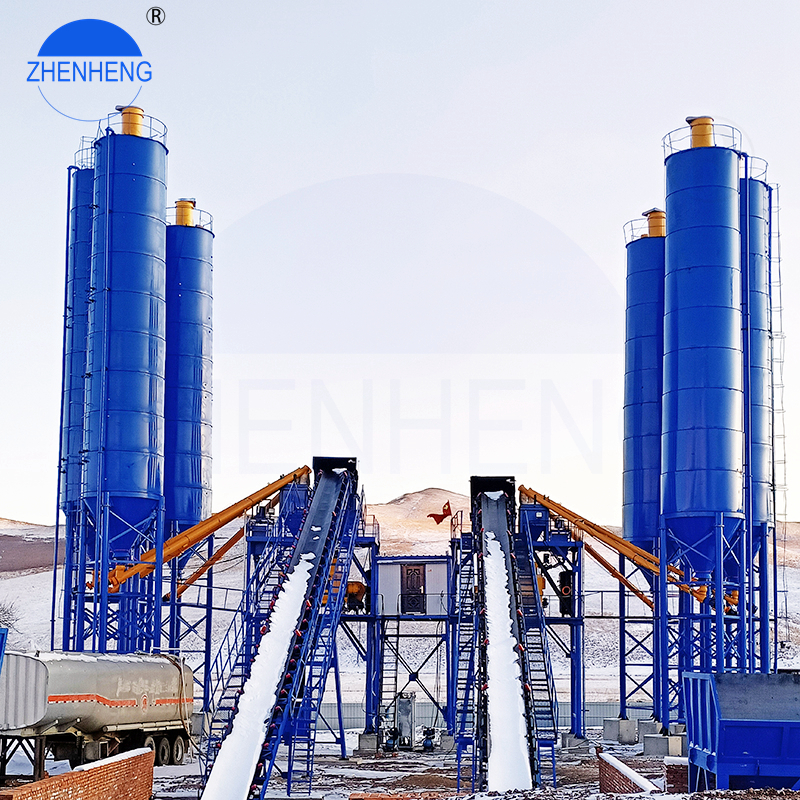

HZS120 120m3/h Stationary Mixing Station Fixed Concrete Batch Plant for Sale in Philippines

Products Description

Stationary concrete batching plant is composed of aggregate batching system, aggregate convey system, batching system, mixing system, electrical control system, water supply system, air supply system, additive supply system, cement conveyor belt and cement silo. It suits to building site and merchandise concrete produce.

It is widely used large scale building works, road and bridge works and concrete products prefabrication plants, and is an ideal equipment to produce commercial used concrete.

Features

1. Short production cycle and large discharge volume, it’s suitable for commercial concrete batching plants.

2. The belt type mixing station has high feeding and transportation efficiency.

It can quickly complete large-scale operation requirements, and improve production efficiency by more than 20%.

3. It can continuously provide feeding, and the transmission distance is relatively large, which can well meet the needs of large-scale mixing plants.

Details

1.Weighing system

The weighing system includes aggregate weighing.water weighing, cement weighing and additive weighing(optional). It is controlled by microcomputer, the weighing is highly accurate and full automatic.

2.Concrete Mixer

JS Series Concrete mixer is double horizontal axle forced mixers can be used for dry and hard, damp-dry and plastic concrete as well as light aggregate concrete and different types of mortar.

2.Concrete Mixer

JS Series Concrete mixer is double horizontal axle forced mixers can be used for dry and hard, damp-dry and plastic concrete as well as light aggregate concrete and different types of mortar.

3. Cement Silo

Zhenheng adopts strong and thick cement silo which is split type, thus can largely save seafreight and it is easy to assembly at installationsite abroad.There is level meter in the cement silo, indicating the cement level; the arc-breaking system guarantee the discharging fluently.

4. Fully Automatic Control System

The controlling is independently completed by PLC with high reliability. Adopted high-accuracy load indicator which is specially designed for industrial control it has the advantages of high reliability, high precision, high efficiency and anti-jamming.

4. Fully Automatic Control System

The controlling is independently completed by PLC with high reliability. Adopted high-accuracy load indicator which is specially designed for industrial control it has the advantages of high reliability, high precision, high efficiency and anti-jamming.

Parameters

|

Model |

HZS120 |

|

Productivity |

120m3/hr |

|

Mixer Type |

JS2000 |

|

Aggregate Number |

4 |

|

Maximum Aggregate Size |

60/80mm |

|

Unloading Height |

4.2m |

|

Aggregate weighing range |

0-4000kg |

|

Cement weighing range |

0-1200kg |

|

Water weighing range |

0-600kg |

|

Additive weighing range |

0-60kg |

|

Fly ash weighing range |

0-600kg |

|

Dimension |

59*20*23m |

|

Cement Silo |

200T |